Laser-Induced Tar-Mediated Sintering of Metals and Refractory Carbides in Air

Publication

ACS Nano

Authors

Xining Zang, Kiera Y. Tai, Cuiying Jian, Wan Shou,Wojciech Matusik, Nicola Ferralis, and Jeffrey C. Grossman

Abstract

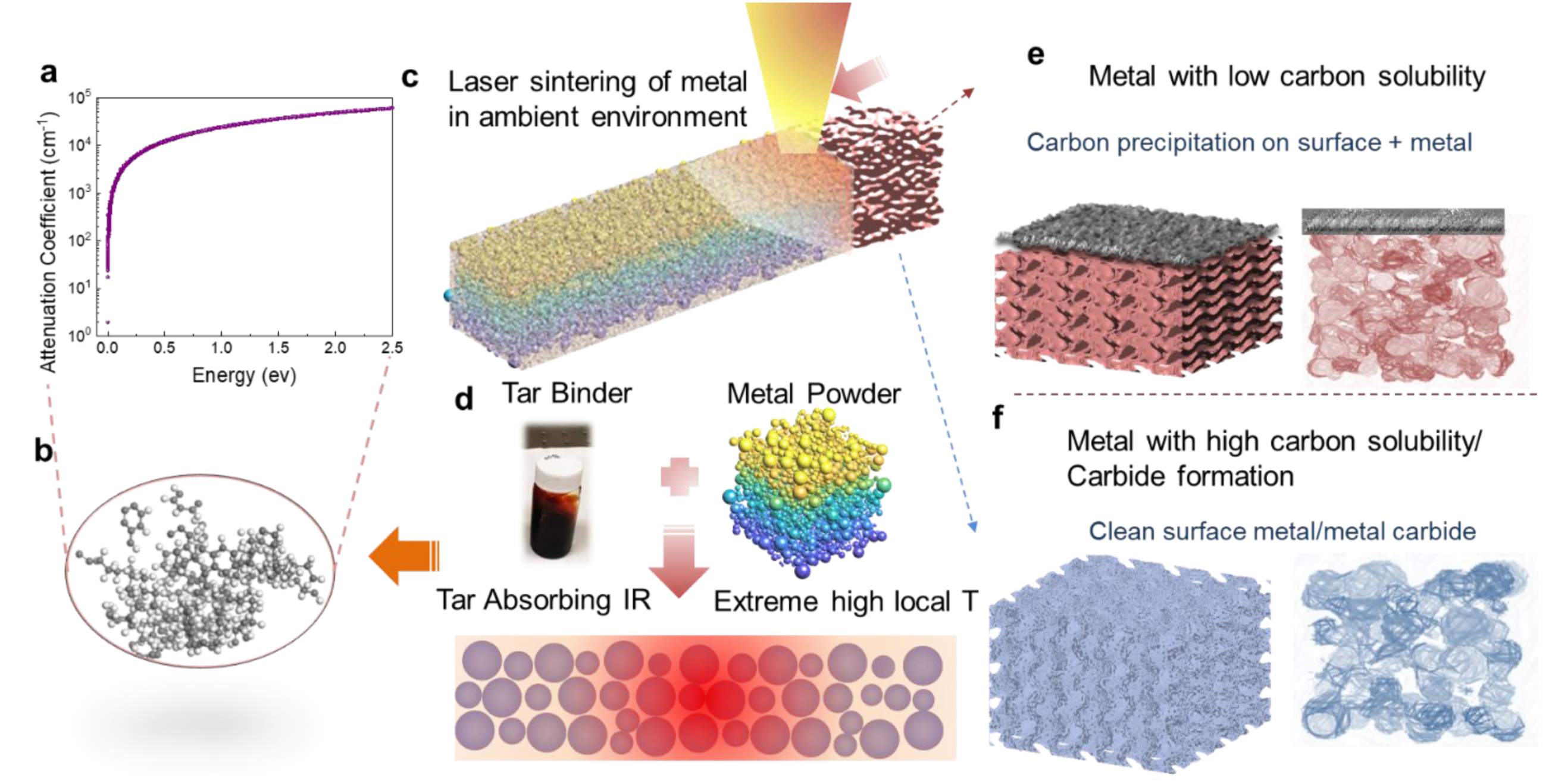

Refractory Metals and their carbides possess extraordinary chemical and temperature resilience and exceptional mechanical strength. Yet, they are notoriously difficult to employ in additive manufacturing, due to the high temperatures needed for processing. State of the art approaches to manufacture these materials generally require either a high-energy laser or electron beam as well as ventilation to protect the metal powder from combustion. Here, we present a versatile manufacturing process that utilizes tar as both a light absorber and antioxidant binder to sinter thin films of aluminum, copper, nickel, molybdenum, and tungsten powder using a low power (< 2W) CO2 laser in air. Films of sintered Al/Cu/Ni metals have sheet resistances of ~10-1 ohm/sq, while laser sintered Mo/W-tar thin films form carbide phases. Several devices are demonstrated, including laser sintered porous copper with a stable response to large strain (3.0) after 150 cycles, and a laser processed Mo/MoC(1-x) filament that reaches T~1000 oC in open air at 12 V. These results show that tar mediated laser sintering represents a possible low-energy, cost-effective route for engineering refractory materials, and one that can easily be extended to additive manufacturing processes.